This example Use Case utilizes the following OAS Platform Components and can be deployed in many different configurations to achieve the best performance and reliability: Learn more about product pricing and request a quote based on your requirements Provides the most robust, scalable, and reliable distributed networking platform for IIoT solutions

SIEMENS SCADA SOFTWARE ANDROID

Read and write data to Allen Bradley, Siemens, and Modbus devices, Universal Drivers, OPC, OPC UA, databases, Excel, and read MTConnect.Ĭonnect to cloud-base IoT gateways such as AWS, Azure IoT, and MQTTīuild custom Visualizations, User Interfaces, HMIs and Dashboards for Windows, web, as well as native iOS and Android devicesĭevelop custom automation apps for Windows, web, and mobile devices. Log events to open databases, and send notifications via SMS, email, and voicemail Log data in open format to MS SQL Server, Oracle, mySQL, PostgreSQL, InfluxDB, MongoDB, SQLite, MariaDB, Access, SQL Azure, Amazon Aurora, Amazon RDS, Amazon Redshift, Google Firebase, and CSV files Historically speaking, the SCADA system has been through some major phases of architecture.The core of the OAS Platform, enabling data connectivity, server-to-server networking, and more This digital data will then be available for the SCADA system. You can connect sensors to the RTU and it will convert their signals to digital data. Since the operational devices like PLC’s and RTU’s are also connected to the server, we can now use the SCADA clients to control and monitor operations.Īn RTU or remote terminal unit is a bit like a PLC. Clients like desktop computers and screens can then function as HMI’s by connecting them to the server. The SCADA application typically runs on a server. It is a whole infrastructure of devices that can communicate. If we take a closer look at the architecture of SCADA it becomes clear, that it contains much more than just HMI’s.

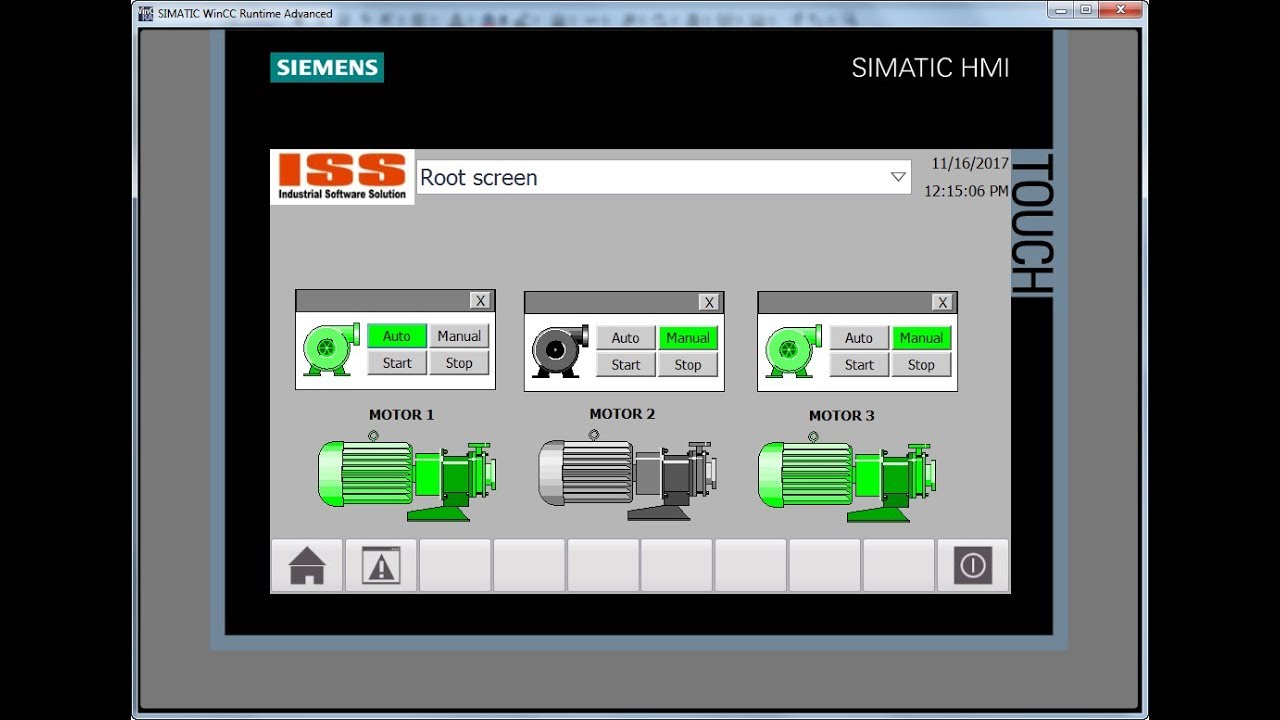

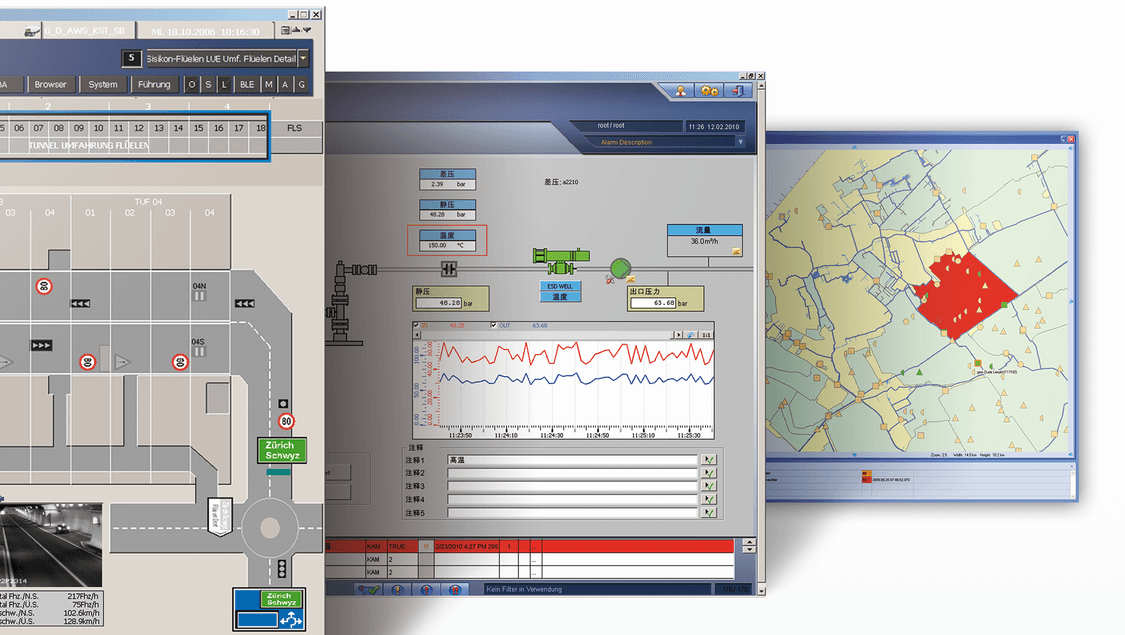

SCADA System Architecture with several HMI’s in a network A SCADA system can have many HMI’s to control and monitor different parts of a plant. Because where the HMI is just the screen or the interface itself, SCADA is an application or a whole system behind all those screens. But now you will often have a touch screen either at the machine or in a control room.īut if all these screen are called HMI, what is SCADA exactly then? Back in the days an HMI was really just a bunch of push buttons and control lamps. They are the interface between the operator and the machine.

SCADA system with PI&D for controlling and monitoringĪll these screens are essentially HMI’s or human-machine interfaces. Most important is it, that the operator understands the different parts of the SCADA system and what they control/monitor. a P&ID (piping and instrumentation diagram). More than often multiple screens where an operator can both control and monitor all relevant components in a unit, machine or even a whole plant. What a SCADA system physically will look like is a screen. Especially the latter is how you will often see SCADA systems in use.

The SCADA basics is really about exchange of information and the ability to control and monitor. Like an order for example.Īgain, the SCADA system is the meeting and connection point between information and operation. Information that has to do with business and planning. But at the same time also to send and receive information from the MES or ERP system above. The job of SCADA is really to control and monitor all this OT. SCADA System in the Automation Pyramid from ISA-95 (IEC 62264-3)īelow the SCADA system is all the operational technology like PLC’s, sensors etc. Right where IT (information technology) meets OT (operational technology). SCADA systems are placed right in the middle of the automation pyramid. And at the bottom you have all the operational systems. At the top you have all the information systems for handling business, planning and logistics. The automation pyramid is a concept published in ISA-95 and IEC 62264-3, in an attempt to describe how different systems work together. SCADA systems are located at the monitoring and supervising level in the automation pyramid. A good way to make an understanding, of what a SCADA system is and where it can be used, is to see it in relation to the automation pyramid. It is widely used in factories to monitor and control production lines and machines. SCADA stands for Supervisory Control and Data Acquisition and is a system for monitoring and controlling and as the name implies, data acquisition.

0 kommentar(er)

0 kommentar(er)